A salt wall that begins to sweat after installation.

A grilling slab that cracks during service.

A spa feature wall that slowly shifts under its own weight.

In most cases, these problems trace back to a single choice made before the order was placed. Salt bricks and salt blocks may come from the same mineral source, but their performance inside a project is very different.

This article is written for buyers planning spa builds, restaurant features, wellness interiors, or bulk material orders—whether it is a first project or a repeat purchase.

Why Most Comparisons Fall Short

Many articles treat salt bricks and salt blocks as interchangeable items. They focus on surface differences while ignoring how salt behaves under load, light, humidity, and transport stress.

Practical issues such as frame pressure, climate exposure, pallet damage, and batch variation rarely get attention. This leaves buyers guessing and installers adjusting on-site. The sections below focus on how each form performs once it leaves the warehouse.

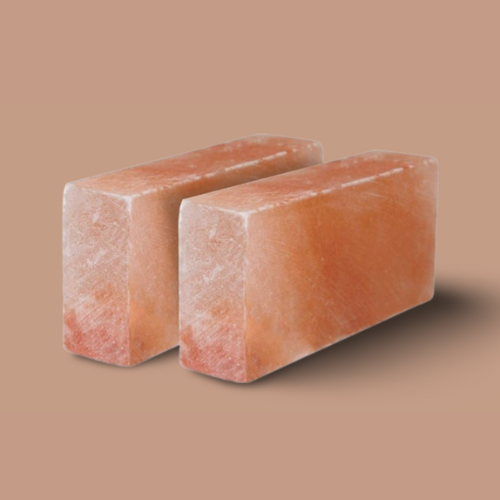

Himalayan Salt Bricks Explained

Salt bricks are rectangular units cut from solid pink salt crystal mined in Pakistan’s Khewra region. They are produced with consistent thickness and straight edges so they can sit securely inside wall frames.

Their shape allows even alignment, controlled spacing, and predictable light diffusion when backlit. Because of this, salt bricks are widely used in wellness interiors and salt room construction where stability matters more than visual texture.

They are commonly installed in halotherapy chambers, spa feature walls, meditation rooms, hotel lobbies, and sauna panels where surface sealing is applied.

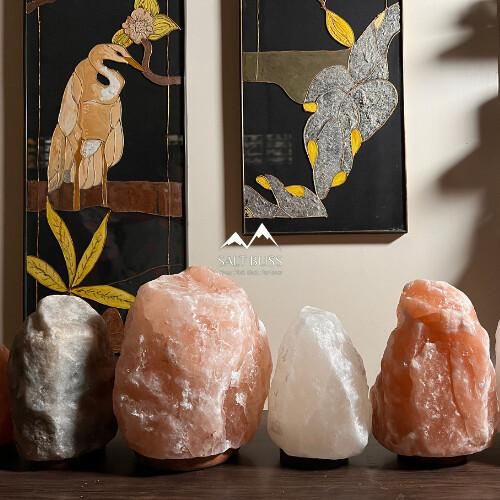

Himalayan Salt Blocks Explained

Salt blocks are thicker, heavier slabs carved from the same crystal source. Their earliest use comes from culinary settings, where salt surfaces are heated or chilled for direct food contact.

Over time, designers also introduced salt blocks into table décor and sculpted installations. Their natural surface variation and mass suit single-piece applications rather than stacked builds.

Due to their weight and irregular sizing, salt blocks are not suited for wall construction or framed installations.

Salt Bricks vs Salt Blocks in Real Projects

The difference between salt bricks and salt blocks becomes clear once installation begins. Salt bricks are shaped for stacking, distribute weight evenly, and sit comfortably inside metal or wooden frames. Salt blocks place higher stress on mounting systems and create uneven joints when stacked.

In backlit walls, bricks spread light consistently, while blocks cause patchy illumination. Moisture also affects blocks faster, especially in humid interiors, because of their surface exposure and thickness.

Application-Specific Use Cases

Halotherapy and Salt Rooms

Salt bricks fit neatly into ventilation layouts and lighting grids. Their spacing supports airflow and long-term wall stability. Salt blocks add unnecessary load and disrupt alignment, increasing the risk of frame distortion.

Spa and Wellness Interiors

Spa walls rely on calm lighting and clean geometry. Salt bricks form uniform grids and maintain a balanced glow. Salt blocks introduce visual irregularity and strain mounting hardware in moisture-prone spaces.

Restaurants and Food Service

Salt blocks perform well as grilling slabs and cold serving plates. They hold temperature steadily and withstand repeated use. Salt bricks are not finished for food contact and should remain outside kitchen environments.

Art and Display Installations

Salt blocks work well for carved pieces and sculptural displays. Salt bricks suit geometric walls, columns, and patterned surfaces. The choice depends on structure, not appearance alone.

Common Buyer Errors

Many buyers assume any pink salt piece can be used for any purpose. Ordering salt blocks for full walls, skipping humidity planning, mixing color batches, or ignoring frame load limits often leads to breakage and uneven results.

Sourcing from traders who cannot confirm mine origin or drying method adds further risk.

Myths and Reality

Salt bricks and salt blocks do not serve the same role. Wall durability depends on crystal density and drying treatment, not color alone. Salt walls also require climate planning; controlled humidity prevents surface sweating and long-term damage.

Details Buyers Rarely Ask About

Salt walls perform better with low-heat LED lighting. Aluminum or stainless-steel frames reduce corrosion risk. Kiln-dried bricks show fewer stress cracks over time. Palletized export packing lowers transit damage, while single-batch color selection keeps wall tone consistent.

These details separate dependable suppliers from short-term sellers.

Buying Notes for Retail and Bulk Orders

Before confirming an order, buyers should verify batch consistency, drying treatment, frame load guidance, export packing method, and mine documentation. These checks protect both small interior projects and container-scale shipments.

Quick Material Choice

Salt bricks suit wall construction, therapy rooms, spa interiors, and hotel features.

Salt blocks suit cooking slabs, serving plates, sculpted décor, and display installations.

Trust Context

Himalayan salt from the Khewra region formed over millions of years and sits far from industrial zones. Salt brick construction is widely used in halotherapy projects, while large installations demand consistent grading and verified sourcing.

Closing Note

Salt bricks and salt blocks share the same mineral source, but their function inside a project is entirely different. Selecting the correct form protects structure, budget, and long-term performance.

Start Your Bulk Order Inquiry

Ready to source export-ready Himalayan pink salt for wholesale or retail packing?

Request product samples, lab certificates, and a price quotation tailored to your order volume.

Contact our sales team today and secure your next bulk shipment with confidence.

FAQs

Ans: No. Their weight and irregular shape create instability in stacked layouts.

Ans: Yes, when sealing and ventilation control moisture levels.

Ans: Salt bricks distribute load evenly and resist stress cracking.

Ans: Yes. They are commonly used for grilling and cold serving.

Ans: Yes. Uniform thickness spreads light evenly.

Ans: Yes. Khewra crystal density provides stronger wall units.

Ans: Established manufacturers handle palletized container shipments.